Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The VA content in EVA elastomers is about 40% to 70%, and EVA elastomers are mainly used as rubber elastomers and PVC modifiers. The higher VA content determines that it is almost or completely amorphous, with a glass transition temperature of about -35 ℃. EVA hot melt adhesive, due to its solvent-free, non-toxic, harmless, non flammable, and environmentally friendly properties, can be widely used in highly automated and high-precision production line operations such as home appliance and automotive assembly and renovation, book binding and edge sealing. It is also widely used in the furniture industry and leather industry.

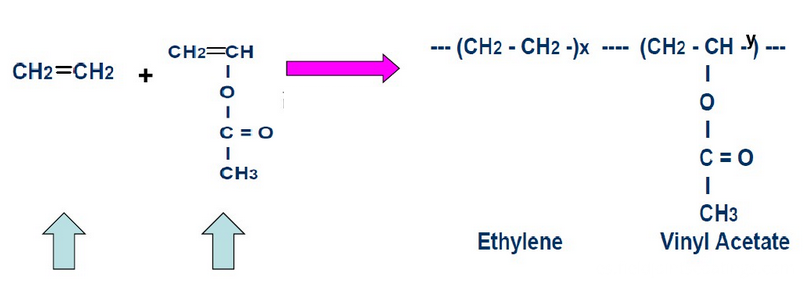

EVA resin

The commonly referred EVA products mainly refer to EVA resin, with a VA content of 5% to 40%. EVA resin can be processed into various products through injection molding, extrusion molding, blow molding, foaming, hot forming, heat sealing, coating, welding and other molding methods, with a wide range of uses. EVA film has the characteristics of good toughness, excellent impact resistance, high transparency, non degradability, non-toxic and harmless, and low shrinkage rate.

EVA lotion

EVA lotion, its VA content is about 70%~95%. Generally, it is produced by lotion polymerization, and the product is in lotion state, mainly used as adhesive, paint, coating, etc. EVA lotion polymerization can obtain polymers with higher relative molecular weight at a faster reaction rate. The viscosity of materials is low, and it is easy to mix and heat transfer. The production process and operation are highly controllable, and residual monomers can be easily removed.

EVA foam material is widely used in the fields of automobiles and footwear, but it has the characteristics of being resistant to puncture, slipping, and low-temperature hardening. Blending and modifying EVA foam can significantly improve the performance of EVA products

EVA resin with a VA content of 12% to 24%, due to its excellent anti fracture and easy cross-linking properties, can be widely used in insulation materials such as wires and cables, to prepare heat shrinkable insulation materials, flame retardant insulation materials, and semiconductor insulation materials. The new silane cross-linked cables and halogen-free flame retardant cables prepared using EVA resin have achieved considerable economic benefits.

As the VA content increases, the polarity of the copolymer increases, causing many properties of the copolymer to change, such as crystallinity, hardness, softening point, rigidity, tensile strength, chemical resistance, heat deformation resistance, etc., to decrease. However, the resistance to environmental stress cracking, permeability, friction coefficient, etc. increase, and the compatibility with other polymers is enhanced, resulting in enhanced printability.

In addition, an increase in VA content will lead to an increase in chain transfer reactions, resulting in a wider molecular weight distribution. Like other polymers, a wider molecular weight distribution mainly affects the fluidity of the melt. This is because in polymers with a wider molecular weight distribution, long chains are more prone to entanglement than short chains, resulting in long chain molecules absorbing most of the deformation energy and exhibiting a higher elastic response. After vulcanization treatment, the changes in performance are relatively complex.

FOREVER Heat Shrinkable Sleeves covered 3LPE Heat Shrink Sleeves, 2PE Heat Shrink Tape, 3LPP Wrap Around Sleeves, HDD Heat Shrink Wrap Sleeves, produced using a special sealed EVA hot melt adhesive and polyethylene substrate. EVA hot melt adhesive is a solvent-free, 100% moisture free solid melt polymer; It is a solid at room temperature, heated and melted to a certain temperature to become a liquid that can flow and has a certain viscosity. EVA hot melt adhesive is composed of basic resin, viscosity enhancer, viscosity regulator, and antioxidant. Due to its solvent-free, environmentally friendly, and high safety, it has the advantage of high adhesive strength. As EVA follows the trend of crude oil, its price fluctuates frequently. When crude oil changes, the market price of EVA will inevitably move. In addition, due to winter maintenance and production restrictions, as well as the arrival of shutdowns, the growth trend of certain chemical raw materials may continue until 2024.

September 02, 2024

December 10, 2023

December 08, 2023

September 05, 2024

September 05, 2024

Contactar proveedor

September 02, 2024

December 10, 2023

December 08, 2023

September 05, 2024

September 05, 2024

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.